DCIM: Think about the connectors!

Source of error: «manual work»

Data centers are making the most of every millimeter. In the computer room, performance has to be increased in order to enable 400G networks. Leaf spine architectures are gaining ground. Racks need to accommodate more channels, fibers, and ports than ever before. The market is now looking for platforms in the high-density class.

How should operators and those responsible for data centers manage the mass of fibers and ports without errors? How can they cope with the increasing complexity of these infrastructures with fewer and fewer staff? How can they guarantee that these networks are securely available around the clock? I’ve been asking myself these questions a lot lately.

Experience shows that errors creep in when things are done by hand. People can forget, overlook or misunderstand something. The most common consequences: security deficiencies, failures, patching errors, incorrect audits, breaches of compliance.

Further acute risks are covered in the Focus article in our specialist magazine CONNECTIONS No. 61.

Time for a paradigm shift

A study by the Uptime Institute suggests that data center operators could prevent about 75 % of known outages. They would have to improve management, tools, and processes and exclude typical homemade errors in cable management and network documentation.

To put it in a nutshell: It is time for a paradigm shift in the management of the physical network level in data centers.

The market already offers a great deal of what is needed for this – Data Center Infrastructure Management (DCIM) and Automated Infrastructure Management (AIM) solutions.

DCIM is available in all shapes, sizes, and complexity. DCIM machines can be used to manage buildings, access, electricity, UPS, temperature, fire protection, resources, assets, cabling, and much more. There are all-powerful, highly intelligent, and modular offerings. None offers unconditional transparency.

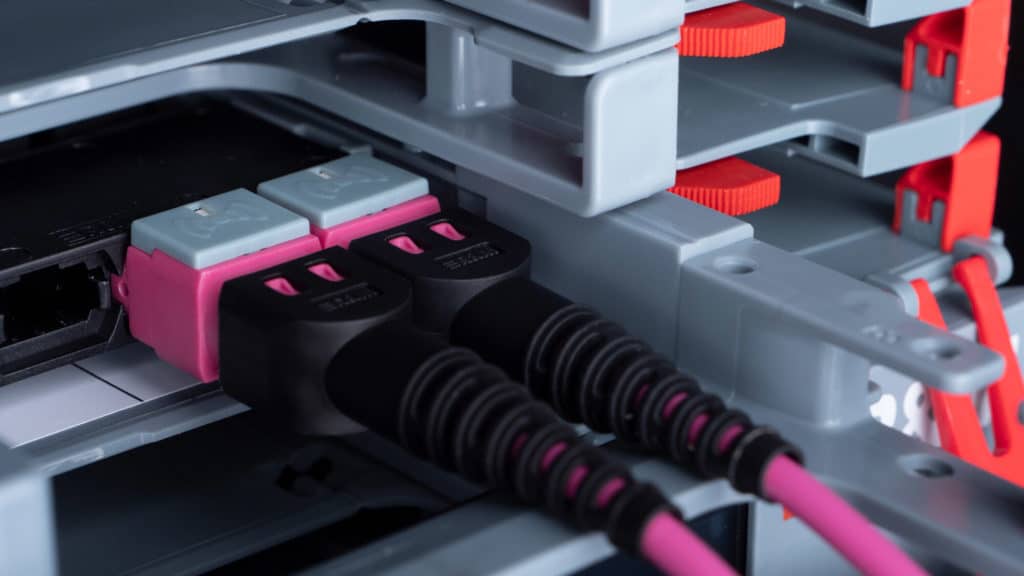

Very few people think about the network connector first. But this small, non-virtualizable part may decide on the availability of an entire data center or a global network.

This is why we at R&M advocate considering DCIM and security from the point of view of connectivity.

Everything depends on the connectors

There is even a dependency relationship. DCIM only works if the right patch cords are inserted in the right port. What happens if critical information does not immediately appear on the operator’s DCIM dashboard?

Hopefully, there is at least one redundant LAN connection, but it doesn’t change the fact that: Availability starts with the connector.

There can be no high security in the data center without 100 % end-to-end control of the passive network layer.

The bottom-up approach for DCIM

Our bottom-up approach – briefly described – is as follows:

- Each connector is given its own singular passive identification.

- Sensors on the patch panel «see» the connectors, read the identifiers and assign them to the ports. That is the intelligence of the connector.

- LEDs show active links, patching jobs, and patching errors live. They «guide» the technicians.

- The sensor system communicates with an analyzer that bundles the connection information from one or more racks.

- All analyzers in one particular system are connected to the on-site server via Ethernet/IP.

- The status of further installations can also be made available to the server via standardized interfaces such as SNMP.

- The operator receives a digital profile of spaces, inventory, racks, and cabling. The server tracks, documents, monitors, alarms and communicates in real-time with other in-house management systems.

- This enables the operator to monitor the status of physical connectivity and other infrastructures in real-time at all times and introduce the necessary measures to maintain performance in good time.

- This makes it easier to comply with contractually agreed SLAs and leads to greater customer satisfaction.

These are the main DCIM/AIM elements. An unbroken digital chain of information is created from the ports to the operator’s dashboard. No connector will be «forgotten» any more. All work is centrally organized and automatically monitored.

If you want to compare the organic bottom-up model with the traditional or complex approaches of infrastructure management, I recommend reading the specialist magazine CONNECTIONS No. 61, page 7.

R&M’s contribution

With the inteliPhy components, the DCIM software inteliPhy net 3.0, and the Netscale Ultra-High Density platform from R&M, data centers can implement the bottom-up model without any stress.

You don’t even have to change the patch panels. The inteliPhy Brownfield Service helps data center operators to make patch panels of every manufacturer «intelligent». This allows them to be integrated into the DCIM. Operators gain a holistic view of their network and its connectivity – in real-time.

DCIM software inteliPhy net 3.0

Have you already tried out the R&M DCIM software inteliPhy net 3.0? Request a free trial version now. You will receive the installation instructions and a test license code for 30 days from us by e-mail.