- Suiza - Español

- Contacto

4PPoE optimized. IDC inside.

Power over Ethernet (PoE) is the technology of choice to provide interference-free data and power simultaneously. By becoming more and more powerful, PoE – and mainly it’s the newest version, 4PPoE – is able to provide up to 90W of power. This puts completely new demands on the data cabling supporting them. PowerSafe products and solutions from R&M guarantee a stable and reliable transmission.

To ensure reliable, long-term 4PPoE capabilities, the following 3 quality factors will have to be followed simultaneously.

To handle increased temperatures, cable installation conditions (cable type, bundle size, cable duct properties) must be considered and the Link length may have to be reduced.

R&M provides the «PoE Calculator» as a planning tool to simulate the various effects involved. Get the Power over Ethernet Calculator for free now.

Depending on the wire diameter of the cable, the current of 4PPoE produces heat. The higher the transmitted power, the higher the generated heat.

Depending on installation conditions (cable bundle size, environmental conditions), the generated heat dissipates differently, and the cable temperature increase.

To mitigate the effects of higher attenuation in a cable with high temperature, link length may have to be reduced.

Un-mating a connection under load will create sparks, that can damage the contacts of the connectors. The higher the transmitted power the higher the destruction. Whether an RJ45 jack is affected depends on the mechanical construction.

With a proper design of the products, the damaged area on the contact is separated from the contact area at rest.

Testing according to IEC60512-99-002 will assure the highest level of resistance against the effects of spark erosion.

Even small increases of resistance in an unsuitable termination can destroy a connector due to overheating.

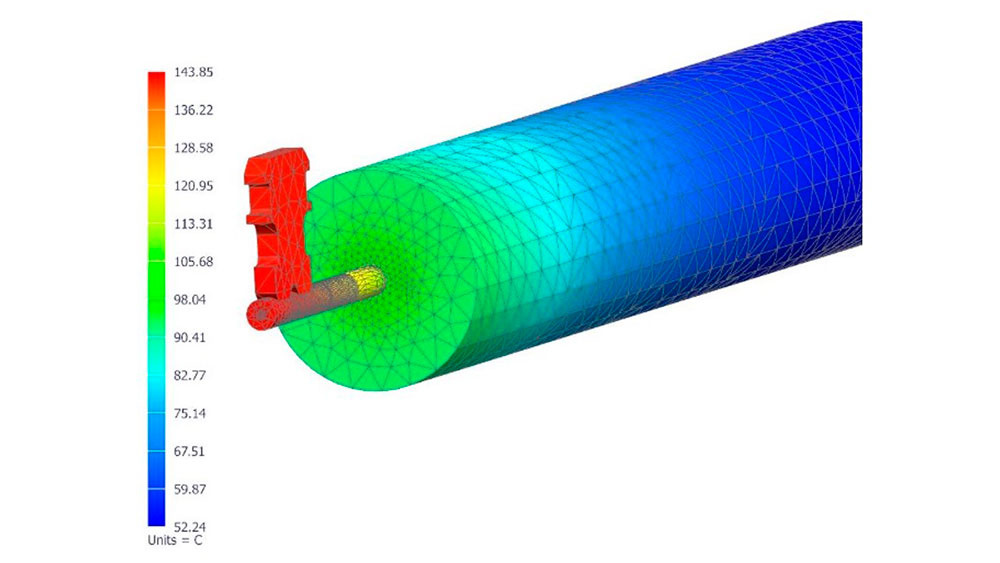

FEM simulations show, that with 4PPoE a contact resistance of 100 mΩ can result in temperatures in excess of 135 °C.

IPC is the most commonly used termination in patch cords. Good initial contact resistance will unduly increase over time.

IDC is the high-quality termination technology, where the wire is fixed between spring-loaded contact arms.

IDC is the termination technology, that will assure low contact resistance over the entire lifetime of the cabling. Ideally suited for 4PPoE.

R&M marks the products using IDC termination technology with the PowerSafe quality seal.

R&M is the only manufacturer of factory terminated patch cords with IDC technology. Only these cords can assure reliable, long term 4PPoE performance.

R&M’s PowerSafe range of patch cords, cable assemblies, connection modules, couplers and field-mountable connectors with insulation displacement contact (IDC) technology offer optimal low resistance wire termination. The reliable IDC termination ensures a consistently low DCRU over the entire lifespan of the product. PowerSafe solu-tions guarantee stable, reliable transmission of interference-free data and power up to 4PPoE.