- Switzerland - English

- Contact

We cannot afford any mistakes or interruptions and need absolutely secure connectivity at all sites.

ACHIM SAX, HEAD OF FACILITY MANAGEMENT, HAMILTON BONADUZ AG

Like a lot of fascinating companies, Hamilton was born in a garage. Clark Hamilton, a chemical engineer who had studied at MIT, set himself a major goal at the end of the 1940s. He wanted to develop a precision tool that could handle the smallest liquid samples and invented the legendary microliter syringe.

In 1953, the pioneer started producing them in his own workshop in Whittier, near Los Angeles, and his precision syringes have been shaping analytical processes in chemistry and diagnostics ever since. Today they continue to sell for the same price as they did when the company was founded.

The company grew quickly and was relocated to Reno, Nevada, in 1960. Six years later Clark Hamilton founded a hub outside America, in Bonaduz, Switzerland. He had fallen in love with the region and the Swiss mountains. Here he wanted to drive forward product development in the spirit of «Made in Switzerland». It also helped to boost sales in Europe.

Today, the family-owned company is the global market leader in the automated handling of the smallest amounts of liquid. The pipettes, miniature laboratories, and sensors set standards in medical technology as well as in the chemical, pharmaceutical, life science, and food industries. Hamilton’s innovations enabled the first automated screening of whole blood for AIDS and hepatitis.

Intelligent ventilators are just as useful. They were developed and have been manufactured since 1983 in Bonaduz by affiliate Hamilton Medical. They provide safer care for critically ill patients. Demand for these quality products has risen sharply during the current pandemic.

Intelligent ventilators are just as useful. They were developed and have been manufactured since 1983 in Bonaduz by affiliate Hamilton Medical. They provide safer care for critically ill patients. Demand for these quality products has risen sharply during the current pandemic.Thanks to the dedication of the Hamilton employees, countless additional hospitals around the world and even the army can be supplied with the equipment and consumables within a very short time. Standardized and highly automated manufacturing processes enable ventilators to be assembled every 40 minutes.

The Hamilton companies develop their locations as dynamically and single-mindedly as their innovations and growth. The most recent key project was the construction of a new production plant with an automated small parts warehouse in Domat/Ems in the Swiss canton of Graubünden.

Before that, Hamilton commissioned Schönholzer AG from Chur to connect the campus with a fiber optic network and modernize the network. A restructured data center had to be reconnected. The installation work had to be carried out during ongoing operations and at high speed.

The question of space was a challenge for the planners and installers from Schönholzer. They had to accommodate the new fiber optic and copper cabling in historically grown routes and channels of the industrial building. «That was really hard work and a leap in time for us,» says Achim Sax, facility manager at Hamilton. Furthermore, infrastructures for the use of Power over Ethernet (PoE) and the Internet of Things (IoT) had to be created. This will enable Hamilton to automate further processes in the future.

Achim Sax explains: «A lot has changed over the last five years. Office and production require more and more IoT, cloud, bandwidth, automation, and collaboration solutions. Everything is becoming more digital and our networks have to be equipped to cope with that. Good connectivity is essential in our branch.»

Despite all the dynamics, the projects succeed with utmost precision. Standardization is the key to success.

Precisely defined manuals for the data centers and cabling systems at the plants in Graubünden as well as for the plant in Romania dictate how copper and FO installations have to be carried out at Hamilton. They contain specifications for network components, nomenclatures, notes on standards, measuring methods, and warranty processes.

Precisely defined manuals for the data centers and cabling systems at the plants in Graubünden as well as for the plant in Romania dictate how copper and FO installations have to be carried out at Hamilton. They contain specifications for network components, nomenclatures, notes on standards, measuring methods, and warranty processes.

Hamilton and R&M developed the manuals together in the interest of a holistic, modular, and expandable infrastructure. Planners and installers must comply exactly with the manuals and specified installation processes. The standards also stipulate that only planners qualified by R&M are admissible.

Achim Sax and his ICT colleague Roman Janett have implicit faith in the R&M products: «They always work.» Quality, operating safety, reliability, and warranties are part of the offers. R&M accompanies each project closely with expertise, project support, logistics, and, in the area of fiber optic cabling, also with measurements.

«We cannot afford any mistakes or interruptions and need absolutely secure connectivity at all sites,» Achim Sax says explaining the consistent standardization and the high demands made of project partners. Because network technology should also contribute to improving people’s lives.

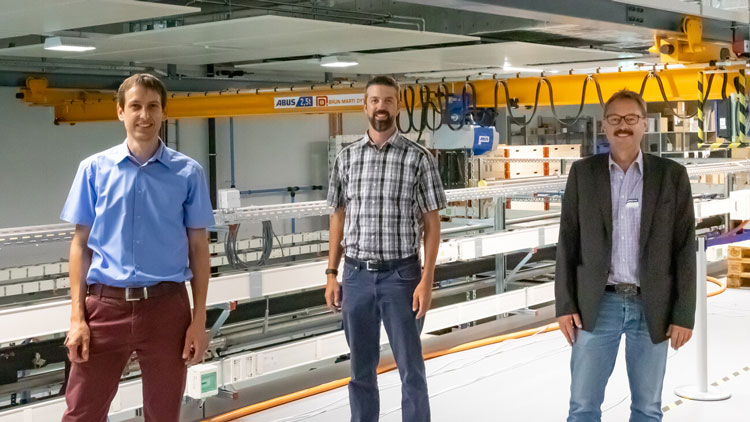

In the new building in Domat/Ems. From left to right: Achim Sax, Head of Facility Management, Hamilton Bonaduz AG; Roman Janett, ICT Network Engineer, Hamilton Bonaduz AG; René Wunderli, R&M Switzerland.